We build the vehicle bodies according to type of vehicle and along phases or production lines which include the following;

Safety is paramount at Alisana Engineering Ltd. Our vehicles surpass safety standards due to rigorous quality control and expert engineering.

Alisana Engineering Ltd offers exceptional vehicles without compromise. Our streamlined processes provide competitive prices without sacrificing quality

We respect your time. Alisana Engineering Ltd delivers on time with meticulous attention to detail, ensuring efficiency and quality.

The frame/chassis is assembled with the engine, gear box, differential, and all other underframe components to form a base on which the body is to be set out.

The chassis is selected in accordance with the clients’ specifications like the desired sitting capacity, the make, the durability and may be the cost. Next, is to drive the frame to a leveled ground ready for the work to start.

An architect now models the Architecture of the bus to be built and this is set out on paper.

Intricate steps define this phase:

All materials are now fully welded to keep them intact. This takes time where experienced welders bond these metals together by welding according to the thickness of the material and the AC level.

The outcome of this process is a fine body skeleton.

This is a way of heating pieces of metal using electricity or a flame so that they melt and stick together.

This is a sculptural/fabrication process that joins materials, usually metals or thermoplastics, by causing fusion which is distinct from lower temperature metal-joining techniques such as brazing and soldering which do not melt the base metal.

There are many kinds of welding:

This is also known as stick welding. It is the most basic type, easy to master for a simple welding station.

It can be used for manufacturing, construction, and repairs. It can also suit for heavy metals of 4mm and above.

This is commonly called MIG welding. It’s the most widely used. It is suitable for fusing mild steel, stainless steel and also aluminium. It can suit for metals of thinner gauge like thin metal sheets and alloys.

We embrace an advanced multiplex wiring system, harmonizing electrical and electronics seamlessly. This simplifies wiring harnesses, enhances diagnostics, and accommodates the elevated electronics in modern vehicles.

Divided into exterior and interior phases:

a. Exterior covering involves the application of metallic plates and/or fiber, achieving a smooth and dent-free surface.

b. Interior covering involves attaching steel, aluminum, or fiber elements through welding or riveting, creating a comfortable and functional interior space.

After the paneling the steel and/or aluminium to their maximum elongation limits to ensure a smooth, dent- and wrinkle-free surface, the exterior of the bus is now molded by pasting with body filler to remove all the dents preparing it to be sprayed. This process leaves the bus ready for painting.

The paint line is elaborate with state-of-the-art giving the bus its characteristic color and sheen post which makes it ready for its final fitments.

It is a very sensitive process. It requires a series of activities to come up with a fine and clear work. They include the following;

This phase starts with patty work where all spots left out during panel beating and filler pasting are filled with spot patty and scratched thoroughly to make the surfaces smooth and more dent free by removing rough parts to make the bus ready for spraying.

Our engineers select, measure and mix color materials or paint to come up with a fine color to be sprayed on a bus body.

Selected color paints are now sprayed on surfaces of the bus.

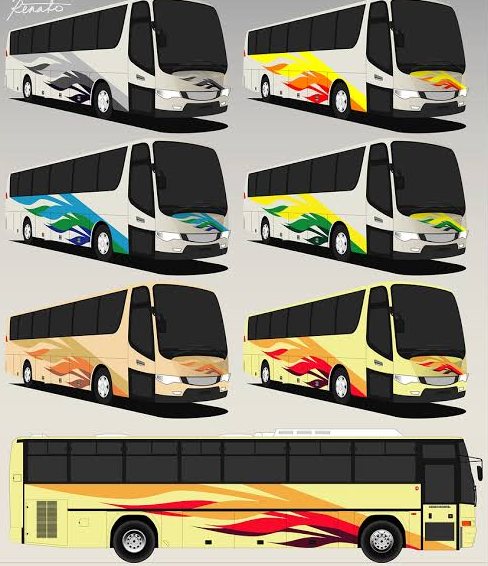

This involves a lot of art work. Our artists come up with clear color designs.

This is done by coming up with pieces of artistic impressions where our client chooses his/her best piece.

The vehicle takes its final form in two phases:

a. Exterior fitment encompasses windscreen installation, window frames, mirrors, and more.

b. Interior fitment adds insulation, flooring, hand grips, and comfortable seats, all meticulously designed for a refined interior.

We also repair vehicles which undergo accidents, and we bring them back to normal like they were before. So never throw away your car that has been dismantled in an accident, we are here to put it back to normal.

Here the branding of the vehicle is made in relation to customer’s specifications.

This involves attaching calligraphic components and designs to give the vehicle a brand name, putting signology demarcations where necessary and also making extra beautification of both the interior and exterior.

Don’t miss our future updates! Get Subscribed Today!

©2024 Copyright. All Rights Reserved BY Alisana Engineering